Technical Specification

Material Sourcing

The raw material is obtained from Highly reputable and trusted sources, or is imported from different countries. We are very careful about the material quality. We always prefer high quality material to manufacture our products.

Identification Of Material

Color codes are used to identify stored raw materials using colors on the face and length of the stored commodity. Each raw material bar is assigned a unique identification number instead of the color code. A record for the identifying number is kept to facilitate supplier and material identification. The bar’s unique identification number is preserved until the entire length of the bar is devoured.

Life On the Shelf

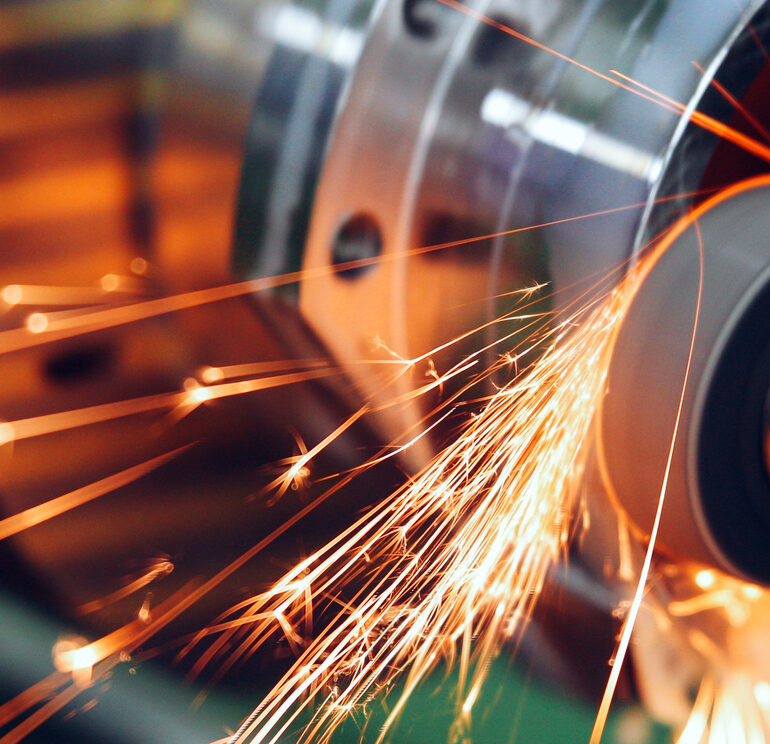

Iron racks hold the raw material. Because the material’s inventory is limited to three months, there is not a requirement for any steps to manage shelf life, etc. Tools are sandblasted prior to finalizing to eliminate any corrosion agents. Rust preventives are applied to tools after grinding and polishing, and they are securely placed in polythene bags & cardboard boxes.

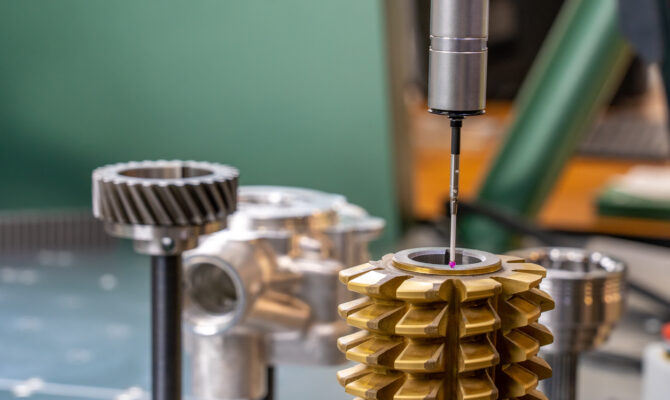

Calibration

Calibration on measurement instruments and testing devices is performed on a regular basis in accordance with BIS using master gauges as well as meters or from outside authorities.

Heat Treatment Process Control

Digital temperature monitors and controllers, infrared type pyrometers, optical pyrometers, and thermocouples are used to control the temperature of the heat treatment furnace.

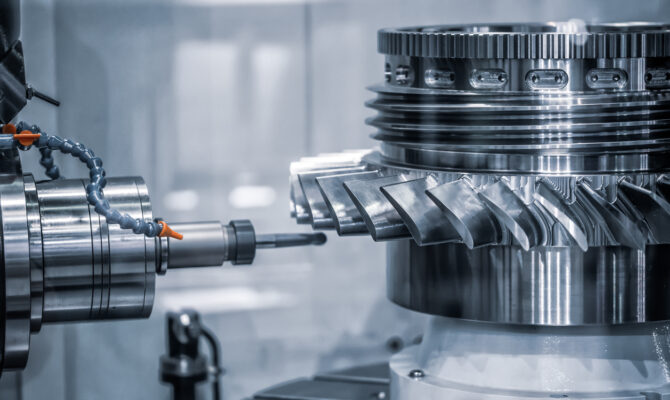

International Inspection

The tool to be manufactured is inspected at each stage of machining by maintaining sufficient Finalizing / Grinding margins and inflation tolerances throughout heat treatment. Following heat treatment, the tools are grounded to close standards as per accepted standards or as per the customer’s special requirements as per drawings, etc.

Maintenance Of Good Records

Quality records for customized as well as conventional tools built to customers’ designs and specifications are kept by generating drawings and keeping a record of the same by assigning a particular task / number of references to facilitate repeat orders.