Master Gears: The Precision Behind Gear Manufacturing

In gear cutting tools manufacturing, precision is paramount. Among the essential tools that drive this precision are Master Gears. These specialized gear cutting tools are the unsung heroes behind the gears that keep machinery and industries running smoothly. In this article, we will dive into the realm of Master Gears, their significance, and how they contribute to achieving gear perfection.

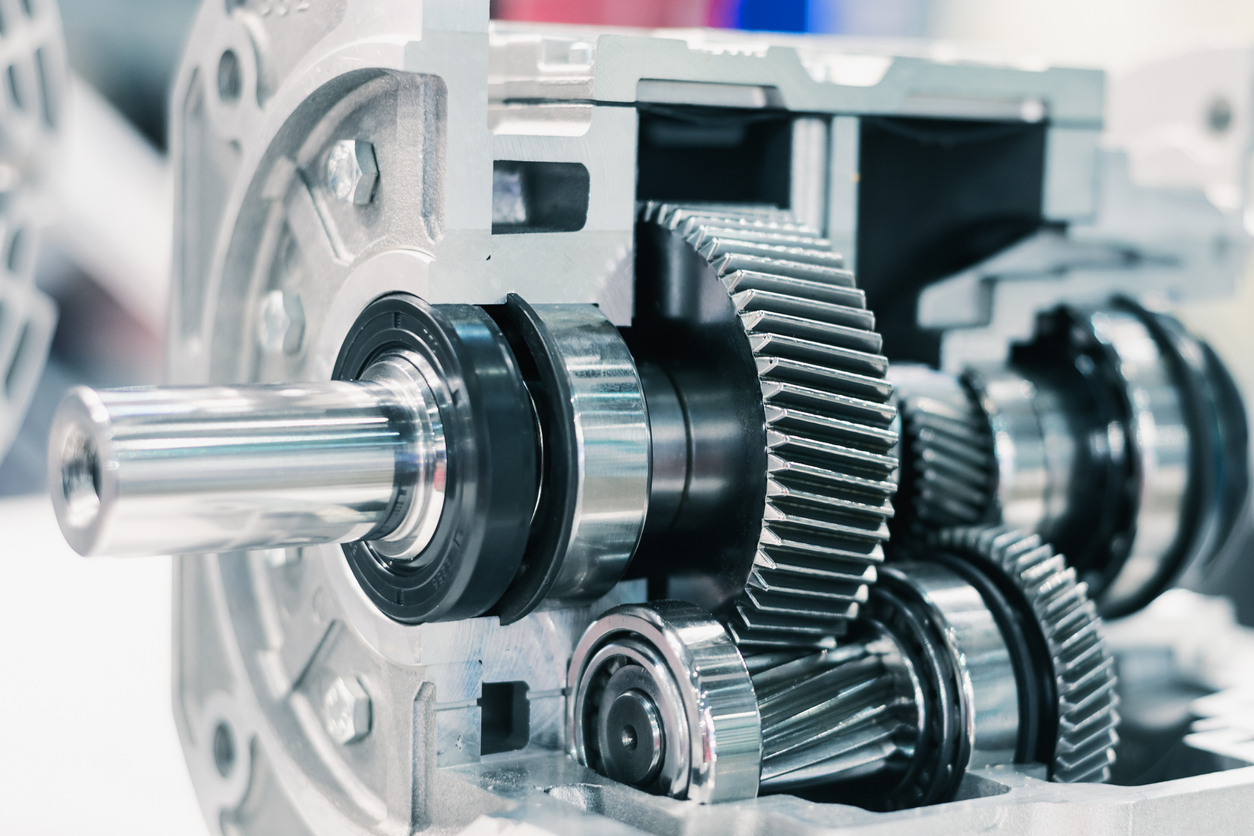

Unveiling the Master Gears

Master Gears, also known as gear masters or gear measuring wires, are precision instruments used to verify and calibrate the accuracy of gear-cutting equipment. They are the benchmarks against which all other gears are measured. These tools serve a crucial role in ensuring that gears produced by gear-cutting machines meet the desired specifications and adhere to stringent quality standards.

The Significance of Master Gears

Master Gears offer several key benefits and play a pivotal role in gear manufacturing:

- Precision Calibration

Master Gears are meticulously manufactured to ultra-high precision standards. They serve as the reference point for setting up gear-cutting machines, ensuring that the resulting gears are accurate in terms of tooth profile, pitch, and other critical parameters.

- Quality Assurance

By using Master Gears for calibration and verification, manufacturers can maintain the highest level of quality control. This leads to gears that operate quietly, efficiently, and with minimal wear, ultimately reducing maintenance costs and prolonging gear life.

- Versatility

Master Gears can be used in various gear-cutting processes, including hobbing, shaping, and grinding. Their adaptability makes them invaluable tools in gear manufacturing across different industries, from automotive and aerospace to industrial machinery.

- Troubleshooting

When issues arise in gear production, Master Gears can be used to diagnose and correct problems. By comparing the gears produced to the reference Master Gear, manufacturers can identify discrepancies and fine-tune their machines for optimal results.

- Precision Gear Manufacturing

Master Gears are a critical component in achieving gears with the tight tolerances required for high-performance applications, such as automotive transmissions, industrial machinery, and aerospace components.

The Heart of Precision Gear Manufacturing

In conclusion, Master Gears are the beating heart of precision gear manufacturing. Their role in calibration, verification, and quality assurance ensures that gears meet the highest standards of accuracy and performance. Whether it’s for producing gears that drive vehicles, machinery, or critical industrial processes, Master Gears are the unsung heroes that guarantee precision in motion.