Elevating Gear Precision to Perfection

Gear Shaving Cutters

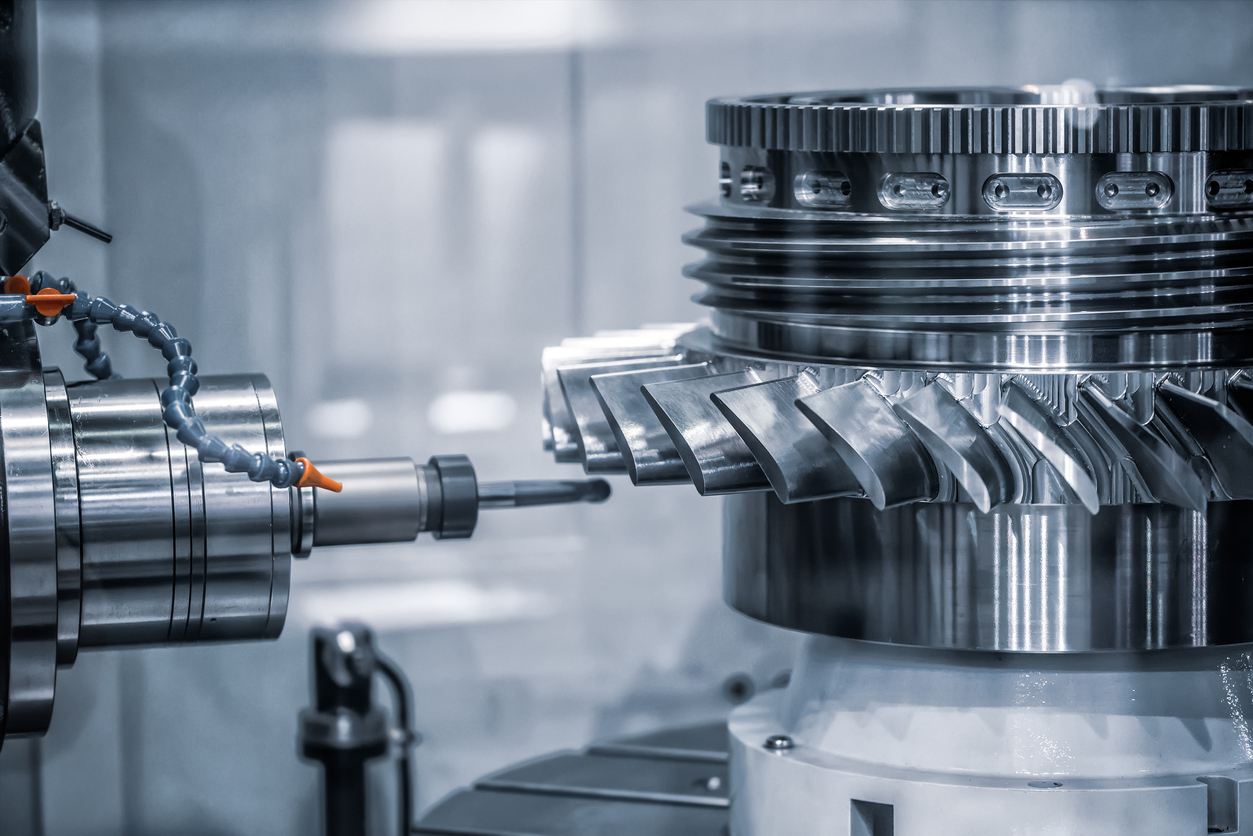

In the intricate world of gear manufacturing, precision is not just a preference – it is an absolute necessity. Gear Shaving Cutters, often heralded as the pinnacle of gear cutting precision, play a pivotal role in crafting gears with exceptional accuracy and surface finish.

The Art of Gear Shaving

Gear Shaving Cutters are specialized tools used in gear manufacturing to achieve unparalleled levels of precision and surface finish on gear teeth. This process, known as “shaving,” involves the precise removal of a thin layer of material from the gear’s tooth surfaces. The result is gears that boast not only exceptional precision but also a smooth, mirror-like finish.

Gear shaving is employed to create gears with minimal noise, enhanced efficiency, and extended durability. This process is particularly crucial for high-performance applications where precision and smooth gear operation are non-negotiable.

The Key Features of Gear Shaving Cutters

Let’s explore some key features and advantages of Gear Shaving Cutters:

Precision Engineering

Gear Shaving Cutters are engineered with meticulous precision. Each cutter is designed to produce gear teeth with consistent dimensions and profiles, ensuring minimal variation and tight tolerances. This level of precision minimizes the need for additional finishing processes and reduces material waste.

Superior Surface Finish

One of the standout qualities of Gear Shaving Cutters is their ability to create gear teeth with exceptionally smooth surfaces. This mirror-like finish not only enhances the aesthetics of gears but also reduces friction, contributing to quieter and more efficient gear operation.

Wide Application Range

Gear Shaving Cutters can be used for a variety of gear types, including helical gears, spur gears, internal gears, and more. Their versatility makes them a valuable tool in the gear manufacturing process.

Enhanced Gear Performance

Gears crafted with Gear Shaving Cutters are known for their outstanding performance characteristics. They operate quietly, with reduced wear and an extended service life. These benefits are especially crucial in demanding applications like automotive transmissions and industrial machinery.

Cost-Effective Manufacturing

While Gear Shaving Cutters are precision tools, they ultimately contribute to cost-effective manufacturing. Their ability to produce high-precision gears with minimal rework and excellent durability leads to long-term cost savings.

Choosing the Right Gear Shaving Cutter

Selecting the right Gear Shaving Cutter is essential to achieving the desired gear quality and performance. Factors such as gear specifications, material type, and production requirements should be considered when choosing the appropriate cutter.

In conclusion, Gear Shaving Cutters are the epitome of precision in gear manufacturing. Their ability to create gears with exceptional accuracy and surface finish makes them an invaluable tool in various industries. Whether it’s for automotive, aerospace, or industrial applications, Gear Shaving Cutters play a pivotal role in elevating gear precision to perfection.